Safeguarding workers against silica dust exposure has become paramount in Australia’s industrial landscape. With increasing awareness of its health hazards, industry experts are turning to innovative solutions for effective mitigation. Among these, the utilisation of advanced vacuum systems stands out as a cornerstone approach.

In industrial operations across Sydney and New South Wales, where stringent regulations govern workplace safety, the adoption of vacuum technologies offers a proactive means to combat silica dust. By implementing high-performance vacuum systems specifically designed for silica dust extraction, businesses can not only comply with regulatory standards but also prioritise the well-being of their workforce. This strategic approach not only mitigates immediate health risks but also ensures sustained productivity and longevity in the competitive Australian industrial landscape.

What is silica dust?

Silica dust is a fine powder made up of tiny particles of crystalline silica, which is a naturally occurring mineral found in materials like sand, stone, concrete, and bricks. When these materials are disturbed through activities like cutting, grinding, drilling, or crushing, silica dust can be released into the air. Inhaling silica dust can pose serious health risks, leading to conditions such as silicosis, lung cancer, and respiratory problems. Therefore, it’s important to implement dust control measures and safety protocols to minimise exposure to silica dust in industrial and construction settings.

What is Respirable Crystalline Silica (RCS)?

Respirable Crystalline Silica (RCS) is a hazardous substance commonly found in various industrial environments, particularly in activities involving cutting, grinding, drilling, or crushing materials such as stone, concrete, brick, and mortar. Here’s a breakdown:

- Definition: RCS refers to very fine particles of crystalline silica, typically smaller than 10 micrometres in diameter, that can penetrate deep into the lungs when inhaled.

- Example: Imagine a construction site where workers are using power tools to cut concrete blocks. As these tools create dust, microscopic particles of crystalline silica are released into the air. If proper safety measures are not in place, workers may inhale these particles, leading to respiratory issues such as silicosis, lung cancer, or other serious health complications.

- Impact: Exposure to RCS can have severe health consequences, including lung diseases like silicosis, lung cancer, and chronic obstructive pulmonary disease (COPD). Therefore, effective dust control solutions and mitigation strategies are crucial to minimise exposure and protect workers’ health.

| Type | Amount |

| Granite | 25 to 40% |

| Shale | 22% |

| Natural sandstone | 67% |

| Composite (engineered or manufactured stone) | >90% |

| Aggregates, mortar and concrete | Various |

Understanding Crystalline Silica and Silicosis:

Crystalline Silica:

Crystalline silica is a naturally occurring mineral found in materials like sand, stone, concrete, and bricks. It exists in various forms such as quartz, cristobalite, and tridymite. When these materials are disturbed through activities like cutting, grinding, drilling, or crushing, tiny particles of crystalline silica can become airborne and be inhaled into the lungs.

Silicosis:

Silicosis is a progressive and irreversible lung disease caused by the inhalation of crystalline silica dust over an extended period. When silica dust particles are inhaled, they trigger inflammation and scarring in the lungs, leading to the formation of nodules and fibrosis. Symptoms of silicosis include coughing, shortness of breath, fatigue, and chest pain. In advanced stages, silicosis severely impairs lung function and increases the risk of other respiratory conditions such as tuberculosis and lung cancer. Prevention through proper dust control measures and workplace safety protocols is crucial in reducing the risk of silicosis among workers exposed to crystalline silica dust.

What tasks in the workplace could cause exposure to respirable silica?

Exposure to respirable silica can occur in various workplace tasks across industries where materials containing crystalline silica are manipulated or disturbed. Here are some common tasks that could lead to exposure:

- Cutting and Grinding: Activities involving cutting, grinding, or polishing materials such as stone, concrete, bricks, or ceramics can generate significant amounts of silica dust.

- Drilling and Crushing: Drilling into concrete, masonry, or rock formations, as well as crushing materials to produce aggregates or powders, can release silica dust into the air.

- Abrasive Blasting: Abrasive blasting operations, such as sandblasting or shot blasting, which are commonly used for surface preparation, cleaning, or etching, can create high levels of silica dust.

- Milling and Sanding: Milling or sanding operations on materials like concrete, stone, or composite materials can produce fine silica dust particles that are easily inhalable.

- Demolition Work: Demolition activities involving breaking, crushing, or dismantling structures made of materials containing silica, such as concrete or masonry, can generate silica dust.

- Foundry Work: Foundry operations, including casting, moulding, or core making, where silica-containing materials like sand or clay are used, can expose workers to respirable silica dust.

- Mining and Quarrying: Mining and quarrying activities, particularly those involving drilling, blasting, or crushing of rock formations, can result in the release of silica dust into the air.

- Tunnelling and Excavation: Tunneling, excavation, or trenching operations in soil or rock formations containing silica can lead to exposure to respirable silica dust.

Implementing dust control measures, such as local exhaust ventilation, wet methods, and using appropriate personal protective equipment (PPE) like respirators, is essential to minimise exposure and protect workers’ health in these tasks. Additionally, proper training, hazard communication, and regular monitoring of airborne silica levels are crucial elements of a comprehensive silica exposure control program.

What do we know about the silica dust exposure standard?

The silica dust exposure standard refers to the permissible exposure limit (PEL) set by regulatory authorities to protect workers from the health hazards associated with respirable crystalline silica exposure. Here’s what we know about it:

- Regulatory Compliance: Regulatory agencies, such as Safe Work Australia and WorkSafe NSW, have established silica dust exposure standards to ensure workplace safety and prevent occupational diseases like silicosis, lung cancer, and respiratory issues.

- Threshold Limit: The silica dust exposure standard typically sets a threshold limit for the concentration of respirable crystalline silica in the air that workers can be exposed to over a specified period, usually an 8-hour workday.

- Measurement and Monitoring: Employers are required to measure and monitor airborne silica dust levels in the workplace to ensure compliance with the exposure standard. This often involves conducting air sampling and analysis using appropriate equipment and methodologies.

- Dust Control Solutions: To meet the silica dust exposure standard, employers must implement effective dust control solutions tailored to their specific work environment and processes. This may include engineering controls like local exhaust ventilation, wet methods, and dust suppression systems, as well as administrative controls and personal protective equipment (PPE).

- Training and Education: Proper training and education programs are essential to ensure that workers understand the risks associated with silica dust exposure, how to use dust control measures effectively, and how to properly use PPE to protect themselves.

By adhering to the silica dust exposure standard and implementing robust dust control solutions, businesses can create safer work environments and mitigate the risks associated with respirable crystalline silica exposure for their employees.

The current workplace exposure standard & duty-of-care

The current workplace exposure standard for silica dust is typically defined by regulatory bodies such as Safe Work Australia or specific state-based agencies like WorkSafe NSW. These standards establish permissible exposure limits (PELs) to protect workers from the health risks associated with respirable crystalline silica exposure.

Under these standards, employers have a legal duty to ensure that workers are not exposed to silica dust levels exceeding the specified limits. This duty extends to providing a safe working environment, implementing effective dust control measures, and providing appropriate employee training and supervision.

Key aspects of the duty of care regarding silica dust exposure include:

- Risk Assessment: Employers must conduct risk assessments to identify tasks and processes in the workplace that may generate silica dust and assess the potential exposure levels.

- Control Measures: Employers are responsible for implementing engineering controls, administrative controls, and personal protective equipment (PPE) to minimise silica dust exposure. This may include dust extraction systems, wet methods, ventilation, and respiratory protection.

- Training and Education: Employers must provide comprehensive training and education to workers on the hazards of silica dust exposure, proper use of control measures and PPE, and procedures for reporting any concerns or incidents related to silica dust exposure.

- Monitoring and Compliance: Regularly monitoring airborne silica dust levels is necessary to ensure compliance with exposure standards. Employers should conduct air sampling, use appropriate monitoring equipment, and maintain records of exposure levels and control measures implemented.

- Health Surveillance: Employers may have a duty to provide health surveillance for workers who are at risk of silica dust exposure. This may include medical examinations to monitor respiratory health and detect early signs of related illnesses such as silicosis.

By fulfilling their duty of care obligations, employers can create a safer work environment and protect the health and well-being of their employees from the adverse effects of silica dust exposure.

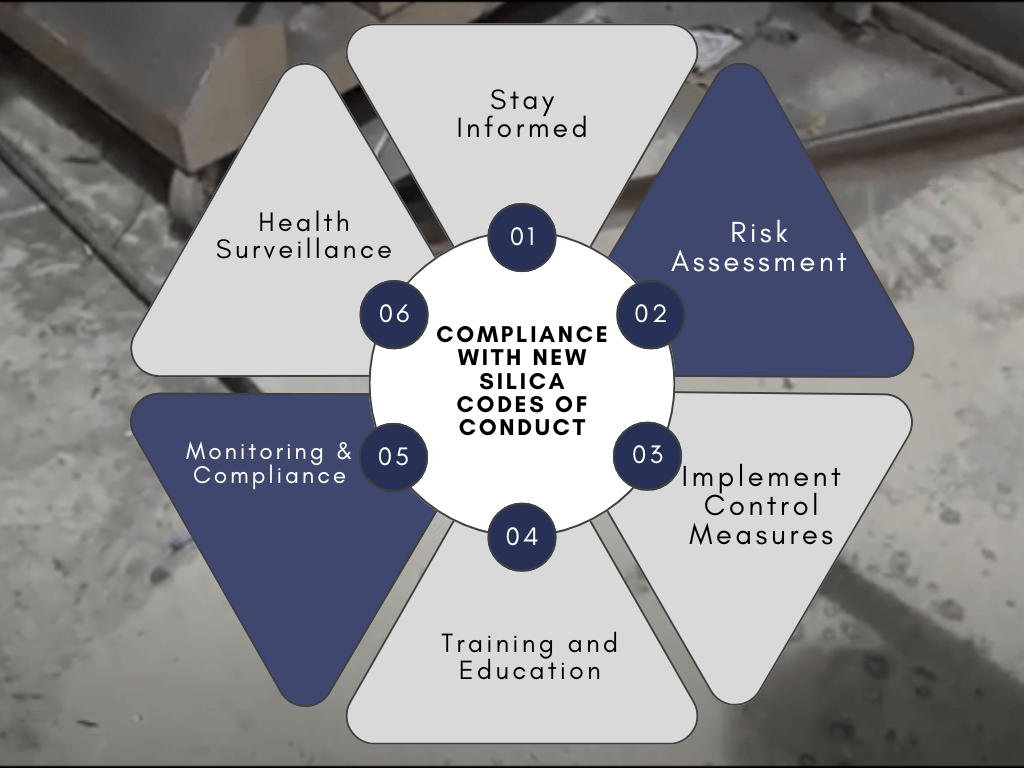

How to maintain compliance with new silica codes of conduct

Maintaining compliance with new silica codes of conduct requires a proactive approach and ongoing commitment to workplace safety. Here are some key steps to ensure compliance:

- Stay Informed: Keep abreast of any updates or changes to silica codes of conduct issued by regulatory authorities such as Safe Work Australia or state-based agencies like WorkSafe NSW. Regularly review relevant legislation, guidelines, and industry standards to understand your obligations.

- Risk Assessment: Conduct thorough risk assessments to identify tasks, processes, and areas in the workplace where silica dust exposure may occur. Evaluate the potential exposure levels and hazards associated with each activity.

- Implement Control Measures: Implement engineering controls, administrative controls, and personal protective equipment (PPE) to minimise silica dust exposure. This may include dust extraction systems, wet methods, ventilation, and respiratory protection. Ensure that control measures are properly maintained and used correctly.

- Training and Education: Provide comprehensive training and education to workers on the hazards of silica dust exposure, control measures, and safe work practices. Ensure that employees understand their roles and responsibilities in maintaining compliance with silica codes of conduct.

- Monitoring and Compliance: Regularly monitor airborne silica dust levels in the workplace to ensure compliance with exposure standards. Conduct air sampling, use appropriate monitoring equipment, and maintain records of exposure levels and control measures implemented.

- Health Surveillance: Consider implementing health surveillance programs for workers who are at risk of silica dust exposure. Provide access to medical examinations to monitor respiratory health and detect early signs of related illnesses such as silicosis.

- Audit and Review: Conduct regular audits and reviews of your silica dust control measures and compliance practices. Identify any areas for improvement and take corrective actions as necessary to maintain compliance with silica codes of conduct.

By following these steps and maintaining a proactive approach to workplace safety, you can effectively manage silica dust exposure risks and ensure compliance with new silica codes of conduct.

Our product recommendation for Industrial Dust Extraction Systems

Our product recommendation for Industrial Dust Extraction Systems

Introducing the Dirt Eater lineup, designed to meet diverse industrial vacuuming needs:

- DIRT EATER JR.: Compact yet potent, these Type H industrial vacuums boast a 45L waste bin and a 7M hose for efficient cleaning in tight spaces.

- DIRT EATER: Featuring Type H cyclonic technology and a powerful 3-stage motor, these vacuums offer dual filtration for thorough cleaning.

- DIRT EATER PROTECTOR: Built for heavy-duty usage, these Type H industrial vacuums come equipped with H14 HEPA filtration for superior air quality.

- DIRT EATER BIG BOSS: Experience legendary performance with these cyclonic industrial vacuums, offering top-notch suction power and reliability.

- Dirt Eater Big Boss (Twin Motor): Ideal for slurry and insulation removal, these vacuums feature twin motors (1400w – 3 Stage American Motor) and a convenient continuous bag system.

- Dirt Eater Bag Dumper: Commercial-grade cleaning made easy with twin motors (1400w – 3 Stage American Motor) and a hassle-free continuous bag setup.

- Dirt Eater Beast: Conquer any mess with this commercial wet and dry industrial vacuum cleaner, boasting a powerful 1400w – 3 Stage American Motor and a spacious 65L waste bin.

From compact solutions to heavy-duty performers, the Dirt Eater range ensures efficient and reliable cleaning for your industrial needs.

In conclusion, Industrial Vacuums and Engineering underscores the critical importance of robust silica dust mitigation strategies within industrial operations. By proactively addressing the risks associated with respirable crystalline silica, we prioritise the health and safety of our workforce. Through the implementation of tailored dust control solutions, including those optimised for Sydney, NSW, and other regions, we aim to minimise exposure and uphold compliance with regulatory standards. From innovative engineering controls to stringent administrative measures and the provision of appropriate personal protective equipment, we are committed to creating a workplace environment that prioritises the well-being of our employees above all else.

As we navigate the complexities of industrial operations, Industrial Vacuums and Engineering remains steadfast in our dedication to excellence in dust control solutions. By fostering a culture of safety and vigilance, we not only safeguard the health of our workers but also cultivate a sustainable foundation for long-term success. Through ongoing education, collaboration, and adherence to best practices, we stand poised to mitigate the hazards of silica dust and pave the way for a safer and healthier future for all.

- Reference

- https://www.worksafe.vic.gov.au/crystalline-silica-safety-basics

- https://www.worksafe.qld.gov.au/safety-and-prevention/hazards/hazardous-exposures/respirable-crystalline-silica

- https://worksafe.nt.gov.au/safety-and-prevention/crystalline-silica-and-silicosis#:~:text=From%201%20July%202020%2C%20the,as%20low%20as%20reasonably%20practicable.